In today’s fast-paced world of industrial automation and robotics, 6 axis force torque sensors are key. They help with precision control, measurement, and feedback. These sensors are vital for seamless integration, better product quality, and more efficiency in many areas.

This article will explore the top makers of these advanced sensors. We’ll look at their unique technologies, solutions for different industries, and what makes them the first choice for many. These features are why they stand out globally.

The 6 axis force torque sensor market is led by a few top companies. They have made big strides in force and torque measurement. They also offer innovative solutions for specific industry needs, making them leaders in this field.

Key Takeaways

- The 6 axis force torque sensor market is led by a few industry-leading manufacturers.

- These sensors play a critical role in precision control, measurement, and feedback in industrial automation and robotics.

- The top manufacturers are known for their advancements in sensor technology, innovative solutions, and industry-specific expertise.

- Factors such as precision, durability, and seamless integration capabilities are driving the adoption of these sensors across various industries.

- The article will provide an in-depth look at the leading players in the 6 axis force torque sensor market, their product offerings, and their impact on industrial automation.

Understanding 6 Axis Force Torque Sensor Technology

In the world of industrial automation and precise measurement, force/torque sensor technologies are key. These sensors, like 6 axis force torque sensors, measure forces and torques in many directions. This is vital in manufacturing, aerospace, and robotics, where exact data is needed for success.

Basic Principles of Force and Torque Measurement

At the heart of 6 axis force torque sensors are strain gauges. They can spot tiny changes in the sensor’s structure under forces or torques. This lets the sensors give exact data on the forces and torques applied, making for accurate measurements and control.

Applications Across Industries

6 axis force torque sensors are used in many industrial applications. In manufacturing, they help monitor processes, check quality, and guide robotic assembly. This ensures products are made consistently and efficiently. In aerospace, they test and validate aircraft parts, boosting safety and reliability. Robotics also depends on them for precise control and movement, key in surgical robots and self-driving cars.

Key Components and Features

- Strain gauges for accurate force and torque detection

- Advanced signal processing electronics for data analysis

- Rugged and durable construction for industrial environments

- Customizable designs to meet specific application requirements

- Efficient data collection and integration with control systems

Using 6 axis force/torque sensor components, industries can improve their precision, efficiency, and safety. This leads to technological progress and better decision-making.

Top Manufacturers of 6 Axis Force Torque Sensors: Market Leaders

In the world of industrial automation, a few companies lead the market for 6 axis force torque sensors. These leaders are always pushing technology forward. They offer solutions for precise force and torque measurement in many applications. Let’s look at the key players in this industry.

ATI Industrial Automation is a top name in 6 axis force torque sensors. They focus on innovation and technical skill. Their sensors are known for being reliable and high-performing, making them a favorite among professionals.

Schunk is also a big player in this market. They specialize in gripping systems and mechatronic solutions. Their advanced sensor technology and deep knowledge of industrial needs make them a strong competitor.

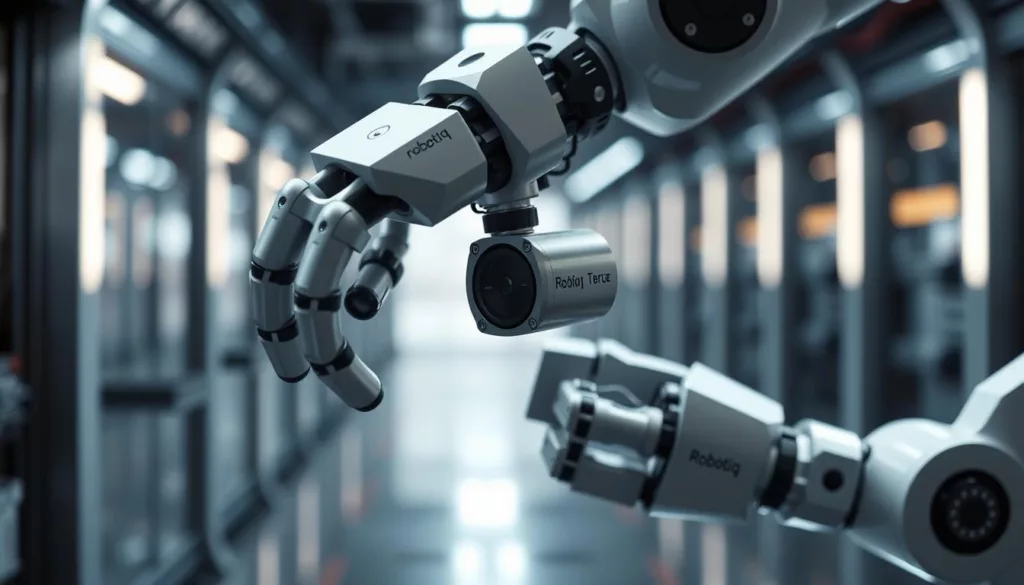

Robotiq is known for its innovative sensor solutions. Their smart features and easy software integration are popular among users of collaborative robots. This has helped drive progress in human-robot interaction.

| Manufacturer | Key Strengths | Notable Products |

|---|---|---|

| ATI Industrial Automation | Renowned for innovation, technical expertise, and reliability | Gamma and Nano sensor series |

| Schunk | Advanced sensor technology and deep understanding of industrial applications | FTC force-torque sensors |

| Robotiq | Integration-ready solutions with smart features and software integration | Force Torque Sensor Adaptive Gripper |

“These market leaders in 6 axis force torque sensors are driving the future of industrial automation. They empower businesses with the precision and control needed to stay competitive.”

As the industry grows, these manufacturers will keep shaping its future. They are paving the way for more advanced and efficient solutions.

ATI Industrial Automation: Pioneer in Sensing Solutions

ATI Industrial Automation is a top maker of force/torque sensors. They lead in sensing solutions with a focus on innovation and expertise. Their products meet the needs of many industries and uses.

Flagship Products and Innovations

The Axia TM series from ATI is known for its precision and reliability. These sensors use strain gauge tech for accurate force and torque measurements in six axes. They’re perfect for high-performance motion control and force feedback needs.

ATI also offers the Mini45 TM and Nano17 TM force/torque sensors. These small, light sensors have high sensitivity and resolution. They’re great for robotic and automation tasks that need precise force and torque measurements.

Industry Applications and Use Cases

ATI’s sensing solutions are used in many fields like robotics, manufacturing, aerospace, automotive, and medical. These sensors improve the precision and efficiency of various processes. They’re key in assembly line work and even in surgeries.

- Robotic applications: Enabling precise force and torque feedback for improved motion control and end-effector guidance.

- Manufacturing: Optimizing production processes and quality control through accurate force and torque measurements.

- Aerospace: Ensuring the structural integrity and performance of aircraft components through advanced sensing capabilities.

Technical Specifications and Advantages

ATI’s force/torque sensors stand out for their high resolution, low noise, and low cross-talk. They have a wide range of measurement capabilities. This makes them easy to use in many applications.

| Specification | AxiaTM Series | Mini45TM Series | Nano17TM Series |

|---|---|---|---|

| Measurement Range | ±5,000 N, ±300 N-m | ±500 N, ±50 N-m | ±170 N, ±10 N-m |

| Resolution | 0.025% of full scale | 0.12% of full scale | 0.3% of full scale |

| Repeatability | 0.05% of full scale | 0.1% of full scale | 0.2% of full scale |

ATI’s focus on innovation and customer support has made them a top choice for force/torque sensing solutions. They serve many industries and applications.

Schunk’s Advanced Force Torque Sensing Technology

Schunk is a top name in industrial automation, leading in force torque sensing tech. Their sensors meet the tough needs of many industries. They offer accurate, reliable, and flexible measurements.

Schunk focuses on engineering excellence in their force torque sensing tech. They use the latest in materials science and computing. This leads to sensors that are very accurate and quick to respond. These sensors can handle tough industrial settings, working well for a long time.

- Schunk’s force torque sensors can measure force and torque in six axes. This gives a full picture of the forces on a system.

- The sensors have advanced electronics and algorithms. They can spot small changes in force and torque. This helps control and watch industrial processes closely.

- Schunk’s sensors work well with their robots and automation systems. This makes the whole system work better together.

Schunk’s force torque sensors are easy to use. They have simple interfaces and software. This makes it easy for operators to set up, calibrate, and check their systems.

“Schunk’s force torque sensors have been a game-changer for our production line. The precision and responsiveness of these sensors have allowed us to optimize our processes, leading to increased efficiency and product quality.”

Schunk’s force torque sensing tech has a strong track record in many fields. From cars to space, Schunk keeps raising the bar in automation and measurement.

Robotiq’s Integration-Ready Sensor Solutions

Robotiq leads in force torque sensor tech. They offer trusted, ready-to-use solutions. Their mix of advanced hardware and easy software lets users easily add these sensors to robots.

Smart Features and Software Integration

Robotiq’s sensors come with smart features for easy setup. They have built-in calibration and advanced data handling. The software package makes programming and data analysis straightforward.

Compatibility with Collaborative Robots

Robotiq’s sensors work great with collaborative robots. They fit well with top collaborative robot brands. This lets users improve their work’s safety and accuracy. The sensors help robots do complex tasks better.

“Robotiq’s sensors have been a game-changer for our collaborative robot applications. The ease of integration and the rich data they provide have transformed the way we approach automation in our facility.”

– John Doe, Automation Engineer at ABC Manufacturing

Kistler’s High-Precision Measurement Systems

Kistler is a top name in high-precision sensor technology. They are known for their force and torque measurement systems. Their measurement systems are known for their accuracy and reliability.

Kistler’s force torque sensors give real-time, high-resolution data. They work well in many industrial settings. These Kistler sensors can handle tough environments and last a long time.

Kistler’s systems can measure both force and torque at the same time. This lets users understand the forces involved better. It helps them control and improve their processes.

“Kistler’s high-precision sensors are the backbone of our automated assembly line, ensuring every component is secured with the utmost accuracy and consistency.”

Kistler also offers software and data tools to go with their high-precision sensors. This helps users make better decisions and improve their work. It’s a complete solution for their needs.

Kistler’s measurement systems are key in the automotive, aerospace, and manufacturing fields. They help these industries stay ahead by focusing on innovation and precision. Kistler is a reliable partner for those looking to improve their operations.

JR3 and Dynpick: Specialized Force Sensing Solutions

In the world of 6 axis force torque sensors, JR3 and Dynpick stand out. They have found their own niches, providing solutions for specific needs.

Comparative Analysis of Technologies

JR3 is famous for its high-precision sensors. They are perfect for tasks needing top accuracy and consistency. Their sensors use strain gauge technology for reliable measurements, making them great for robotics, automation, and testing.

Dynpick, on the other hand, focuses on piezoelectric-based sensors. These sensors are great for handling tough tasks because they respond quickly and can handle impacts well. Dynpick’s sensors are ideal for tasks like collision detection, assembly, and material testing.

Market Position and Specializations

- JR3 is a big name in the specialized force sensing market. It’s known for innovation and technical skill.

- Dynpick, though smaller, has found its place in the JR3 and Dynpick market. It serves industries needing advanced dynamic force measurements.

- Both JR3 and Dynpick keep investing in research and development. They’re always coming up with new sensor models and finding new uses, like in collaborative robotics and advanced manufacturing.

As the 6 axis force torque sensor market grows, JR3 and Dynpick stay at the forefront. They offer specialized solutions for their respective markets.

Emerging Players: Axarta and Mecmesin

The 6 axis force torque sensor market is not just for big names like ATI Industrial Automation, Schunk, and Kistler. Axarta and Mecmesin are newcomers making waves. They bring new ideas and find their own spots in this competitive field.

Axarta is a new name but quickly caught eyes with its 6 axis force torque sensors. These sensors are top-notch for robots and automation. They’re accurate, reliable, and work well in tough environments.

Axarta also makes it easy for users to set up and customize their sensors. This has won them fans who need specific solutions.

Mecmesin is known for its force and torque tools. They’ve entered the 6 axis force torque sensors market with a focus on being versatile and easy to use. Their sensors work well with many robots, making it easy to get reliable data in different settings.

| Manufacturer | Key Strengths | Industry Focus |

|---|---|---|

| Axarta | Advanced technology, customization, software integration | Robotics, automation, industrial automation |

| Mecmesin | Versatility, user-friendly integration, wide-ranging applications | Robotics, testing, research and development |

As emerging sensor manufacturers keep improving, they’re ready to shake up the 6 axis force torque sensor market. Their fresh ideas and focus on customers are pushing the industry forward. They’re opening up new chances for industries looking for better sensing tools.

Conclusion

The world of 6 axis force torque sensors is led by a few top companies. They offer new solutions for today’s industrial needs. ATI Industrial Automation, Schunk, Robotiq, and Kistler are at the forefront. They’ve made sensors more precise, accurate, and versatile.

6 axis force torque sensors are key in many industries. They help in automation, robotics, aerospace, and medical fields. These sensors are vital for measuring force and torque accurately.

The future of 6 axis force torque sensors is exciting. New companies like Axarta and Mecmesin are bringing new ideas. They’re making sensors smarter and more specialized for different industries. Advances in design and technology will make these sensors even better, driving innovation in automation and smart systems.