The field of medical robotics is quickly changing. High-performance sensors are very important here. They help make robotic surgeries more precise and efficient. This is changing how we care for patients. Thanks to improvements in sensor technology, makers can now create sensors that go beyond the tough demands of robotic surgery tools.

We’re looking at the top companies making these important sensors for medical robots. They’re coming up with new solutions for many medical areas. We’ll talk about the tech progress that’s making these sensors more common in health care. This will give you a good view of the industry today and what it could do in the future.

Key Takeaways

- The integration of high-performance sensors is vital for enhancing robotic surgery precision.

- Manufacturers are leveraging advanced medical sensor technology to innovate robotic solutions.

- Robotic surgical equipment now features sensors that improve operational efficiency.

- Leading manufacturers are continuously evolving their products to meet healthcare demands.

- Understanding the landscape of sensor manufacturers helps inform procurement decisions.

- Innovation in sensor technology facilitates better patient outcomes and procedural success.

- Future trends in the industry promise further advancements in sensor capabilities.

Introduction to Medical Robotics Sensors

High-performance sensors are key in medical robotics. They make surgeries and diagnosing better with high accuracy. They also lower the risks and help patients recover faster. As technology grows, new types of sensors are improving healthcare robotics.

Importance of High-Performance Sensors

Medical devices depend on high-quality sensors. These sensors track vital signs and help with difficult surgeries. They make robotic systems work better and faster.

- Accuracy: High-performance sensors give exact data. This allows for precise measurements during important procedures.

- Operational Safety: Sensors help medical robots find problems and warn doctors. This lowers the chances of mistakes.

- Patient Outcomes: Better sensors mean better results for patients. They recover quicker and get care that meets their needs more closely.

Emerging Trends in Medical Robotics

The medical robotics field is seeing new breakthroughs. Mixing artificial intelligence with sensors is a big step forward. This combo improves how decisions are made. It allows robots to adjust their actions during operations.

| Trend | Description | Impact |

|---|---|---|

| Automation | More use of robots for automatic surgery tasks. | Less human mistakes and more efficiency. |

| AI Integration | AI helps with on-the-spot thinking and support during surgery. | Makes surgeries more accurate and response times quicker. |

| Connectivity | Better sensor connection with hospital data systems. | Makes sharing information smoother and patient care better. |

Key Manufacturers in Medical Robotics

In the world of medical robotics, having top-notch sensors is key. We’ll look at the top companies making a big impact in this area.

Overview of Leading Brands

Here are the big names in the medical sensor world:

- Medtronic – Known for their cutting-edge sensor tech in surgeries.

- Siemens – They provide high-end imaging sensors for robotic surgery.

- GE Healthcare – This company is all about new sensor technology for better diagnosis and care.

Innovations from Each Manufacturer

Each of these companies is pushing boundaries with their inventions:

- Medtronic has made tiny sensor systems that fit right into robot-aided surgery. This makes patient results better.

- Siemens is all about the best imaging tech. It helps surgeons be more accurate.

- GE Healthcare puts a lot of effort into research. They’re creating sensors that make robots work better.

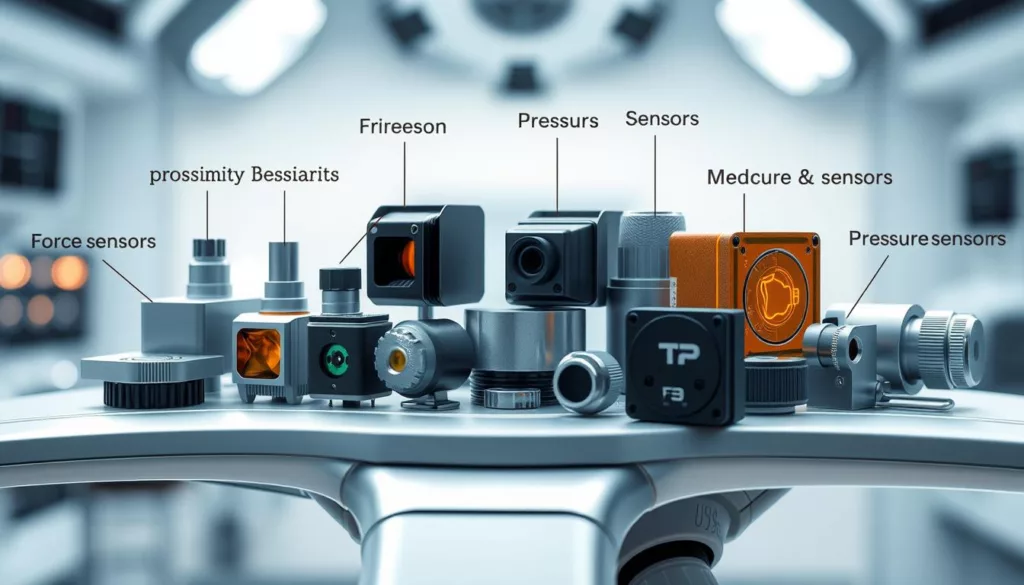

Types of High-Performance Sensors

It’s key to know the different sensors in medical robotics. They help improve surgical methods and medical imaging. High-performance sensors boost accuracy, safety, and results in surgery.

Pressure Sensors in Medical Robotics

Pressure sensors are vital in surgery safety and success. They monitor and control forces during surgery accurately. These sensors give feedback, helping surgeons adjust and avoid complications.

Vision Sensors and Their Applications

Vision sensors greatly improve how surgical robots work. They help guide tools very accurately during surgery. Using them in less invasive surgeries has changed old methods, giving clearer views and better results. Many studies highlight these technologies’ role in better surgery methods.

Pressure and vision sensors are both crucial to medical robotics’ growth. They show how far this technology has come. For more on sensor technology, see TDK’s sensor innovations and XJCSENSOR’s work in medical robotics.

Factors to Consider When Choosing a Manufacturer

When picking medical sensor manufacturers, there are vital factors to look at. It’s essential to check their quality and commitment to sensor tech improvement. Quality standards and research work show if a maker is reliable and if their products work well in healthcare.

Quality Assurance Standards

For medical sensors, following strong quality rules is a must. Standards like ISO 13485 help shape systems for medical devices. Being in line with FDA and CE rules proves sensors are safe and work as needed. A maker focused on these standards will likely offer dependable medical sensors.

Research and Development Contributions

Improving sensor tech takes a lot of research and growth. Companies such as Boston Scientific and Philips invest heavily in innovation. This effort boosts product quality and keeps them leading in the market. Their ongoing research work meets healthcare’s changing needs, making patient care better.

| Manufacturer | Quality Assurance Standards | R&D Commitment |

|---|---|---|

| Boston Scientific | ISO 13485, FDA compliant | High investment in innovations |

| Philips | CE marking, ISO standards | Continuous product development |

| Medtronic | ISO certification, FDA approved | Extensive research funding |

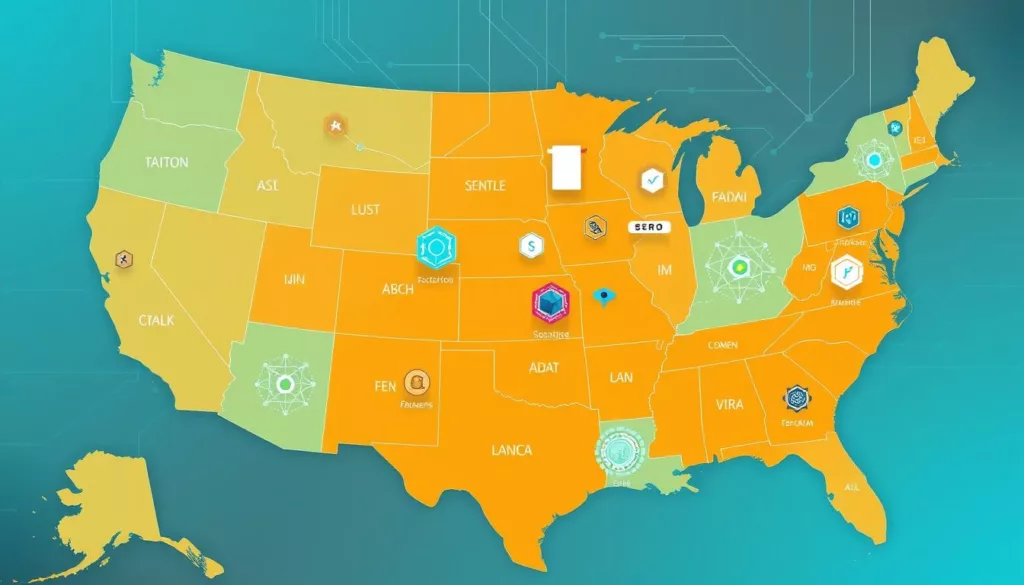

Regional Breakdown of Leading Manufacturers in the U.S.

Exploring regional sensor makers in the U.S. shows how location affects medical robot tech. Each area brings unique skills and new ideas. This is especially true in the Northeast and the West Coast.

Northeast Innovations in Sensor Technology

The Northeast leads with top-notch tech, thanks to companies like Boston Scientific. They improve medical sensors for better robotic surgery. Their dedication to innovation results in major leaps that boost diagnostics, patient care, and device efficiency.

West Coast Leaders in Robotics

The West Coast is a frontrunner in robotics, with Intuitive Surgical leading the way. Their work in robotic surgery systems is a model for others. This area blends tech with healthcare, ensuring robotics enhance patient care through new developments.

| Region | Key Companies | Focus Areas | Innovations |

|---|---|---|---|

| Northeast | Boston Scientific | Medical Sensors, Robotics Surgery | Advanced Diagnostics |

| West Coast | Intuitive Surgical | Robotic Systems | Enhanced Surgical Precision |

This review of regions shines a light on the special roles U.S. sensor producers play. By tapping into local advances, they cement their roles in medical robotics. This pushes healthcare tech into the future.

Case Studies: Successful Implementations

Medical robotics is changing healthcare in big ways with advanced sensors. These sensors play a key role in sensor integration in surgical robotics and rehabilitation robotics using advanced sensors. They improve how doctors perform surgery and how patients recover. By looking at real-life examples, we can see the huge benefits these technologies bring to both doctors and patients.

Sensor Integration in Surgical Robots

There are many success stories of using high-tech sensors in surgical robots. These sensors give detailed feedback that makes surgeries safer and more precise. For example, adding optical and force sensors to robots has made surgery outcomes much better. It also cuts down on the time surgeries take. Studies have shown fewer complications and faster recovery times thanks to these sensors. This proves how valuable sensor integration in surgical robotics is in the medical field.

Enhancements in Rehabilitation Robotics

Improving rehab robots involves high-quality sensors. These sensors track patients’ recovery and help tailor their therapy. They make sure each patient receives care that matches their healing pace. Clinical tests show that these advanced sensors make therapies more effective. This leads to better health outcomes for patients. A key player in this field is XJCSENSOR. They supply sensors that offer precise data for better rehab management. Their innovative approach helps the healthcare industry provide top-notch care for patients. Learn more about their work here.

Future Trends in Sensor Technology for Medicine

The medical tech landscape is changing fast. Soon, we’ll see big changes in sensor technology. These changes will make healthcare sensors smaller and more connected. This is great for patient care and making things run smoother.

Miniaturization of Sensors

Healthcare sensors are getting smaller. This is good for surgery and less upsetting for patients. Smaller sensors mean easier procedures, faster recovery, and happier patients. They fit into medical gear easily without losing quality.

Advancements in Sensor Connectivity

Wireless tech and the internet of things (IoT) will change how we handle medical data. Better connectivity means doctors can watch over patients’ health in real time. They can act fast, using up-to-date info. This helps patients get better care quickly.

Challenges Facing Manufacturers

Making medical sensors involves many hurdles. These affect how products are made and when they reach the market. It’s vital to understand these issues to succeed in the medical device field.

Supply Chain Issues

Supply chains have faced major disruptions recently. This has made getting materials for medical devices harder, causing delays. Problems like geopolitical tensions, changes after the pandemic, and parts shortages have made things tough. These issues threaten the on-time delivery of essential, high-tech sensors.

Regulatory Compliance

Staying up-to-date with rules for making medical sensors is a must. This means following guidelines from the FDA and global health organizations. Not doing so can lead to delays and fines. Constant regulation changes demand thorough testing and validation. This makes making devices even more challenging. To avoid risks and work more effectively, it’s important for manufacturers to keep up with these rules. For more details on these challenges, check out our guide.

Conclusion and Industry Outlook

The medical sensor industry has changed a lot because of high-performance sensors. These sensors have made surgeries more precise and improved how we take care of patients. They are key to many new methods in surgery and rehabilitation.

Looking forward, medical robotics has an exciting future, thanks to sensor advancements. Companies are ready to use these new developments to meet healthcare needs better. They aim to make devices smarter, smaller, and more connected. This will lead to new opportunities in healthcare technology.

Want to learn how we can help with your sensor needs? Visit our contact page. It’s important to stay up-to-date with both challenges and breakthroughs in this area. By working together, we can push towards a future where advanced tech helps healthcare pros do amazing things for patients.