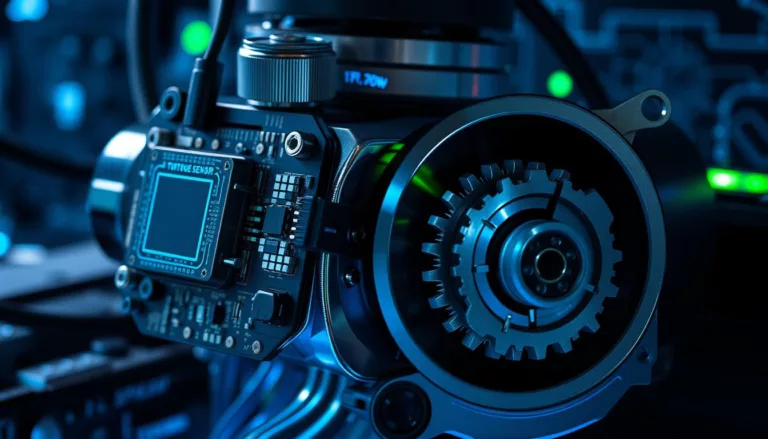

High-Precision Torque Sensors for Industrial Use

Torque sensors are vital tools in industrial automation, quality control, and machinery diagnostics. XJCSENSOR, a trusted manufacturer and supplier, offers high-precision torque sensors designed to capture accurate measurements for applications in robotics, automotive, and industrial automation.

- Exceptional Sensing Precision

- Durable in Demanding Environments

- Adaptable Configuration Options

- Integration-Friendly Design

- Rapid and Accurate Response

INTRODUCTION TO TORQUE SENSORS

Torque sensors measure rotational force and are critical for applications where precise torque measurement is required. They convert mechanical input into readable data, enabling operators to monitor and control machinery. XJCSENSOR’s torque sensors deliver high accuracy and reliability, providing valuable data for applications in various industries, including automotive testing and industrial automation.

Explore Our Torque Sensor Range

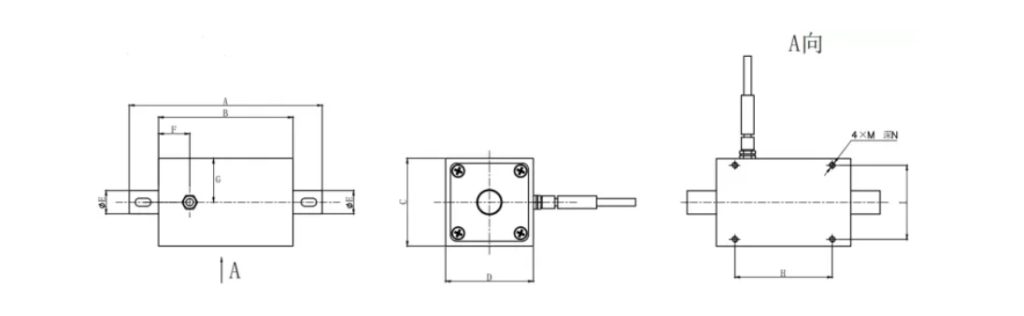

Dynamic Torque Sensor

Model :X-DT-1001

Technical Parameter:

- Output sensitivity: 1.0±10%mV/V

- Max rotate speed: 200r/min

- Non-linearity: ≤±0.2%F.S.

- Repeatability: ≤±0.1%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~60°C

- Compensated temp range: -10~40°C

- Insulation resistance: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10V

- Limit load: 200%F.S.

- Cable size: φ4x4m

- Protection class: IP64

- Temp effect on output: ≤±0.2%F.S./10℃

- Temp effect on zero: ≤±0.2%F.S./10℃

- Cable Connection: Ex+: Red; Ex-: Black; Sig+: Green; Sig-: White

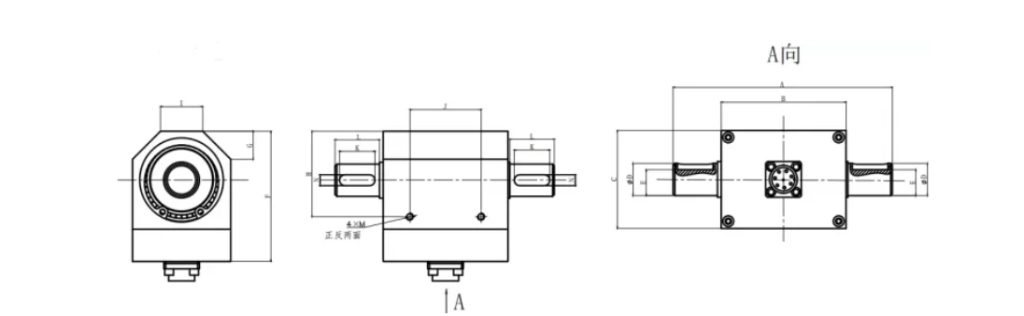

Model :X-DT-1002

Technical Parameter:

- Output sensitivity: 0.5-1.0mV/V

- Max rotate speed: 500r/min

- Non-linearity: ≤±0.2%F.S.

- Repeatability: ≤±0.1%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~60°C

- Compensated temp range: -10~40°C

- Insulation resistance: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Limit load: 200%F.S.

- Cable size: φ4x2m

- Protection class: IP64

- Temp effect on output: ≤±0.2%F.S./10℃

- Temp effect on zero: ≤±0.2%F.S./10℃

- Cable Connection: Ex+: Brown/Red; Ex-: Black; Sig+: Green; Sig-: White

Model :X-DT-2001

Technical Parameter:

- Output sensitivity: 0-10V/RS485

- Max rotate speed: 5000r/min

- Non-linearity: ≤±0.2%F.S.

- Repeatability: ≤±0.1%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~60°C

- Compensated temp range: -10~40°C

- Insulation resistance: ≥2000MΩ/50VDC

- Recommended excitation voltage: 24VDC

- Limit load: 200%F.S.

- Cable size: φ5x4m

- Protection class: IP64

- Temp effect on output: ≤±0.2%F.S./10℃

- Temp effect on zero: ≤±0.2%F.S./10℃

- Cable Connection:24V+: Red; 24V-: Black; Analog output+/RS485+: Green; Analog output-/RS485-: White; Reset: Brown

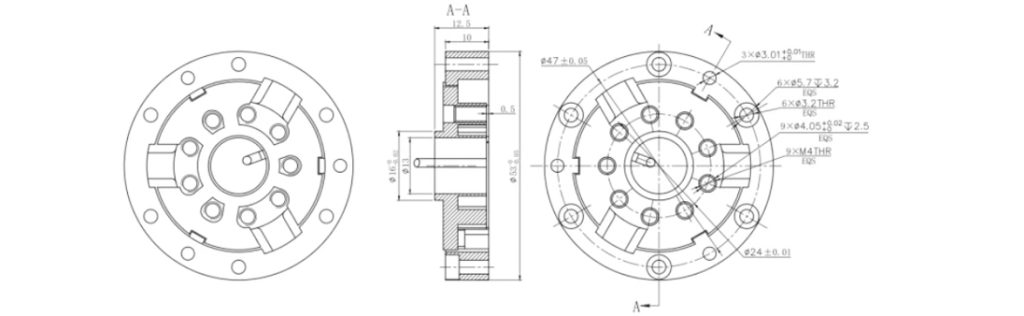

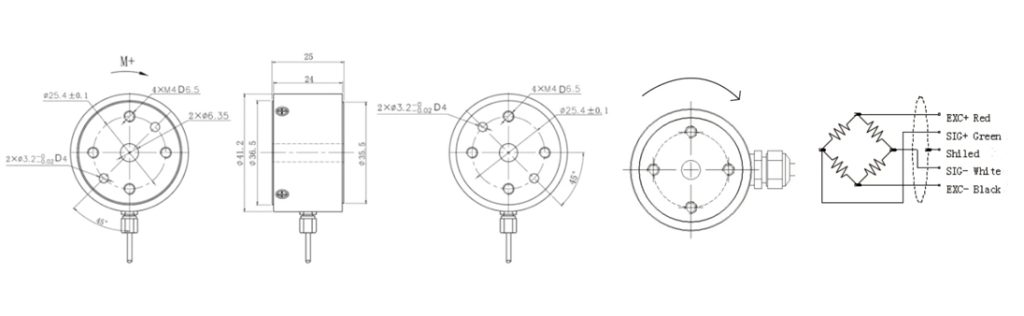

Joint Torque Sensor

Model :X-ST10

Technical Parameter:

- Non-linearity: ≤0.5%F.S.

- Repeatability: ≤1%F.S.

- Zero balance: ±2%F.S.

- Rated output: 1.5V-3V(M+), 1.5V-0V(M-)

- Temp effect on output: 0.2%F.S./10°C

- Temp effect on zero: 0.2%F.S./10°C

- Insulation: ≥2000MΩ/50VDC

- Operating voltage: 24VDC

- Compensated temp range: -10~40°C

- Operating temp range: -20~80°C

- Limit load: 200%F.S.

- Breaking load: 300%F.S.

- Protection class: IP64

- Torsional rigidity: 80(KNm/rad)

- Cable size: φ2*1m

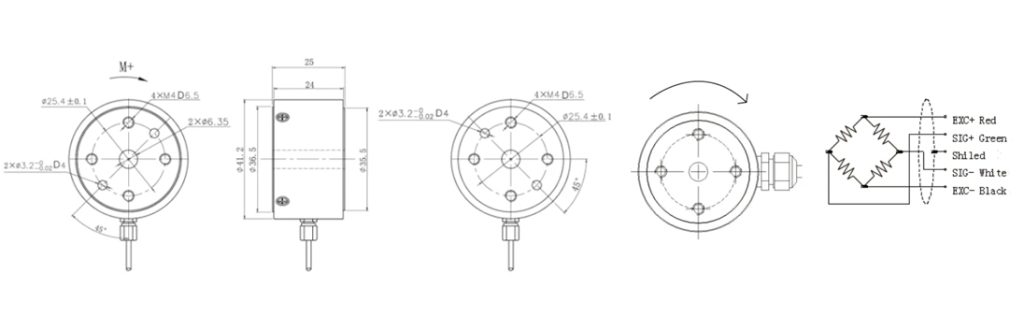

Model :X-ST75

Technical Parameter:

- Non-linearity: ≤0.2%F.S.

- Repeatability: ≤0.2%F.S.

- Zero balance: ±2%F.S.

- Rated output: 1.0±10%mV/V

- Communication: SPI

- Sampling frequency: 2000Hz

- Temp effect on output: 0.2%F.S./10°C

- Temp effect on zero: 0.2%F.S./10°C

- Insulation: ≥2000MΩ/50VDC

- Operating voltage: 12-30VDC

- Compensated temp range: -10~40°C

- Operating temp range: -20~80°C

- Limit load: 200%F.S.

- Breaking load: 500%F.S.

- Protection class: IP64

- Torsional rigidity: 75(KNm/rad)

- Cable size: φ2*1m

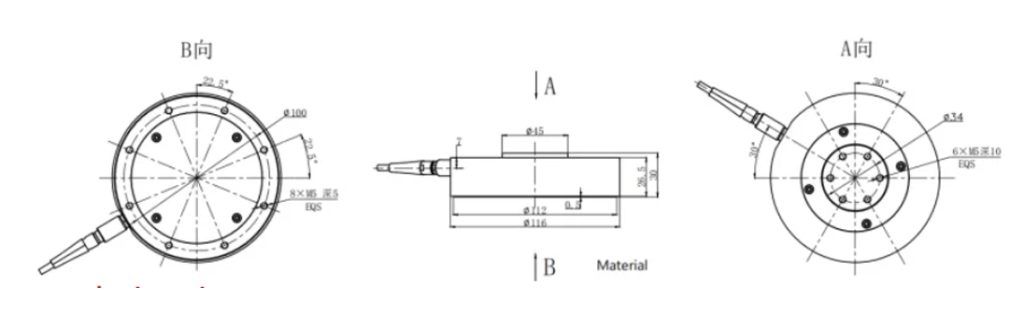

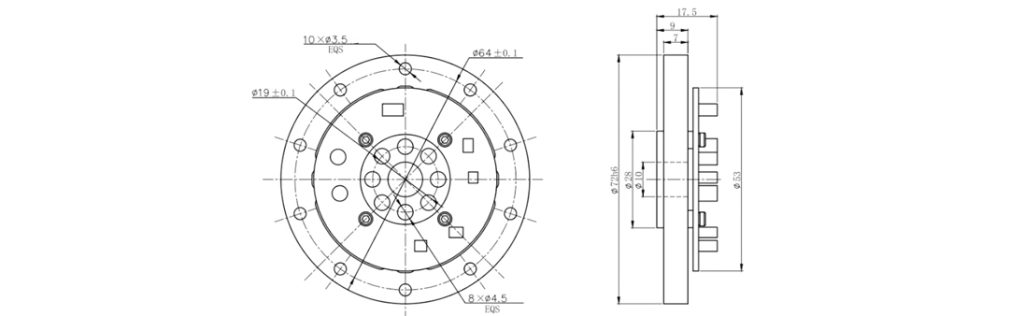

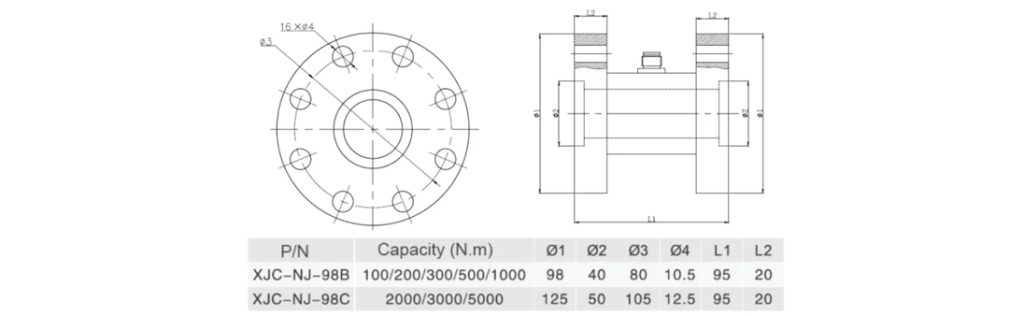

Torque load cell

Model :X-ST-98B

Technical Parameter:

- Capacity: 0-500N.m

- Driving voltage: 12VDC

- Zero balance: ±2% F.S.

- Rated output: 1.0~2.0 mV/V

- Limit load: 120%

- Temp effect on zero: ±0.1% F.S./10°C

- Response frequency: 100Hz

- Compensated temp range: -10~40°C

- Material: Alloy steel

- Operating temp range: -20~80°C

- Combined accuracy: 0.2% F.S.

- Insulation: ≥5000MΩ/100VDC

- Input impedance: 700±10/350±10Ω

- Output impedance: 700±5/350±5Ω

- Cable Connection: Ex+: Red; Ex-: Green; Sig+: Yellow; Sig-: White

- Please refer to the sensor verification certificate, if plug seat number causes the color change.

Model :X-ST-A

Technical Parameter:

- Capacity: 0-150N.m

- Material: Aluminum alloy, Alloy steel

- Non-linearity: 0.1% F.S.

- Rated output: 1.5~2.0 mV/V

- Recommended excitation: 5-10VDC

- Maximum excitation: 15VDC

- Protect class: IP64

- Compensated temp range: -10~40°C

- Hysteresis: 0.1% F.S.

- Operating temp range: -20~80°C

- Repeatability: 0.1% F.S.

- Insulation: ≥5000MΩ/100VDC

- Input impedance: 450±50Ω

- Output impedance: 350±3Ω

- Creep (30min): 0.1% F.S.

- Temp effect on output: 0.05%F.S./10°C

- Zero balance: ±2%F.S.

- Temp effect on zero: 0.05%F.S./10°C

- Limit load: 150%

- Breaking load: 200%

- Cable size: Ø3 x4m

- Life: Full scale more than 1 million times

- Cable Connection: Ex+: Red; Ex-: Black; Sig+: Green; Sig-: White

Model :X-ST-B

Technical Parameter:

- Capacity: 0-100N.m

- Material: Aluminum alloy, Alloy steel

- Non-linearity: 0.2% F.S.

- Rated output: 1.5~2.0 mV/V

- Recommended excitation: 5-10VDC

- Maximum excitation: 15VDC

- Protect class: IP64

- Compensated temp range: -10~40°C

- Hysteresis: 0.2% F.S.

- Operating temp range: -20~80°C

- Repeatability: 0.2% F.S.

- Insulation: ≥5000MΩ/100VDC

- Input impedance: 380±30Ω

- Output impedance: 350±3Ω

- Creep (30min): 0.2% F.S.

- Temp effect on output: 0.05%F.S./10°C

- Zero balance: ±2%F.S.

- Temp effect on zero: 0.05%F.S./10°C

- Limit load: 150%

- Breaking load: 200%

- Cable size: Ø3 x4m

- Life: Full scale more than 1 million times

- Cable Connection: Ex+: Red; Ex-: Black; Sig+: Green; Sig-: White

BENEFITS OF HIGH-PRECISION TORQUE SENSORS

BENEFITS of high-precision torque sensors include increased control over machinery, improved safety, and enhanced product quality. XJCSENSOR’s torque sensors offer precise data, enabling automated systems to operate more efficiently and with better control.

Key Benefits:

- Accurate torque measurement for better control

- Enhanced machine safety through real-time monitoring

- Improved quality control in production processes

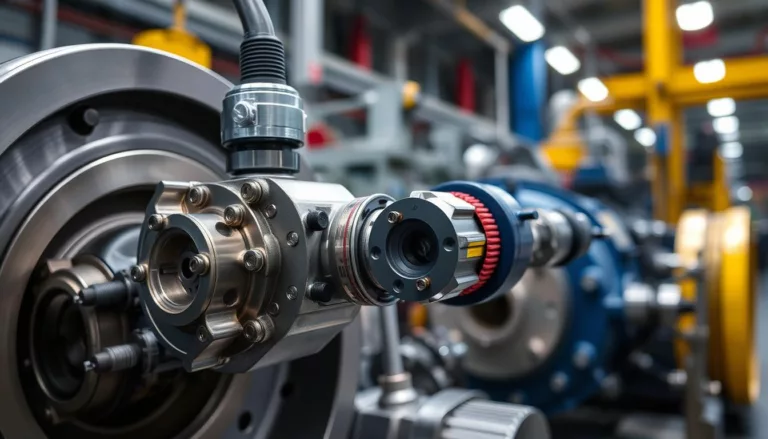

INDUSTRIAL APPLICATIONS OF TORQUE SENSORS

INDUSTRIAL applications for torque sensors are extensive, particularly in environments that require continuous monitoring of machinery. XJCSENSOR’s torque sensors are ideal for controlling and measuring rotational force in industrial automation, manufacturing, and machinery diagnostics, helping companies maintain high standards in production.

Applications Include:

- Machinery diagnostics and maintenance

- Force measurement in automation systems

- Torque control in assembly lines

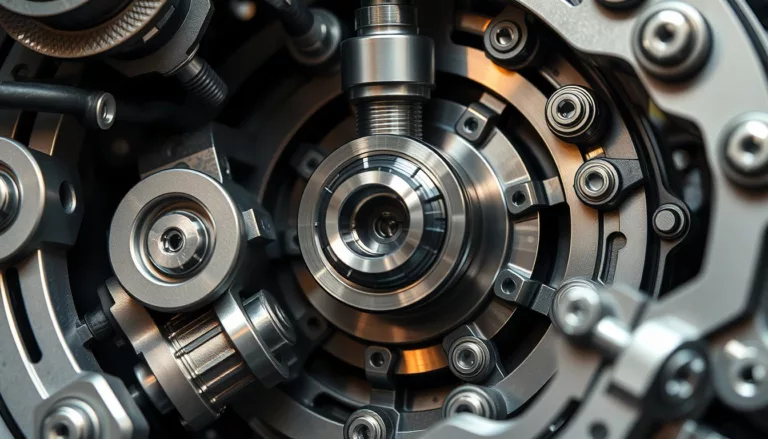

TORQUE SENSORS FOR AUTOMATION AND ROBOTICS

AUTOMATION and ROBOTICS depend heavily on torque sensors for precise motion control and force measurement. XJCSENSOR’s torque sensors provide accurate real-time data, supporting tasks such as robotic gripping, manipulation, and motion control, ensuring productivity and safety in automated processes.

TYPES OF TORQUE SENSORS FOR SPECIFIC APPLICATIONS

TYPES of torque sensors offered by XJCSENSOR cater to diverse applications across industries, ensuring customers can find a solution tailored to their needs.

- Rotary Torque Sensors – Ideal for continuous torque measurement in rotating equipment.

- Reaction Torque Sensors – Best suited for static torque applications.

- Compact Torque Sensors – Designed for use in tight or space-constrained environments.

REAL-TIME TORQUE MEASUREMENT FOR ACCURATE CONTROL

REAL-TIME torque measurement is crucial for applications requiring immediate feedback. XJCSENSOR’s torque sensors provide accurate real-time data, enabling operators to make instant adjustments to maintain optimal performance. This real-time data is especially valuable in applications where small deviations can impact product quality or system efficiency.

STRAIN GAUGE TECHNOLOGY IN TORQUE SENSORS

STRAIN gauge technology is widely used in torque sensors to ensure precise, reliable measurements. XJCSENSOR’s torque sensors incorporate advanced strain gauges, allowing for consistent torque measurement in harsh environments. This technology is especially useful in applications requiring sensitive torque readings, such as automotive testing and precision machining.

Advantages of Strain Gauge Torque Sensors:

- High sensitivity and precision

- Durability for demanding industrial conditions

- Reliable data in varying environmental conditions

CUSTOMIZED TORQUE SENSOR SOLUTIONS FOR INDUSTRY NEEDS

CUSTOMIZATION is a significant advantage for industries with unique sensor requirements. XJCSENSOR offers customizable torque sensor solutions to meet specific operational needs, including custom ranges, dimensions, and environmental adaptations. Our team collaborates closely with clients to ensure each sensor integrates seamlessly into their systems.

QUALITY CONTROL WITH TORQUE SENSORS

QUALITY control relies on accurate torque measurement to ensure products meet specific standards. XJCSENSOR’s torque sensors offer precise, real-time data, allowing manufacturers to monitor torque levels during production and detect deviations early. This helps improve consistency, reduce waste, and enhance product reliability.

WHY XJCSENSOR IS A TRUSTED PROVIDER OF TORQUE SENSORS

TRUST in XJCSENSOR’s expertise and commitment to quality makes us a preferred provider of torque sensors. Our sensors are manufactured to the highest industry standards, offering exceptional accuracy, durability, and reliability. XJCSENSOR’s focus on customer satisfaction and innovation ensures that our torque sensors meet the demands of modern industrial applications.

Conclusion

Torque sensors are essential components in industrial and robotic applications, providing critical data for monitoring and controlling rotational force. XJCSENSOR’s torque sensors deliver reliable, high-accuracy measurements, supporting industries in achieving optimal control, efficiency, and product quality.

With customizable options and advanced technology, XJCSENSOR offers torque sensors that address diverse needs across applications. Trust XJCSENSOR for your torque measurement needs, where precision and quality are at the forefront.