Introduction

Force sensors play a critical role in various industries by providing precise force measurements that enhance safety, efficiency, and automation. Whether in robotics, industrial automation, automotive applications, or medical devices, selecting the right force sensor is essential. This article explores different types of force sensors, their working principles, applications, and advantages.

What is a Force Sensor?

A force sensor, also known as a force measurement sensor, is a device that detects force applied to an object and converts it into an electrical signal for analysis. These sensors are used in weight measurement, pressure detection, and motion control applications.

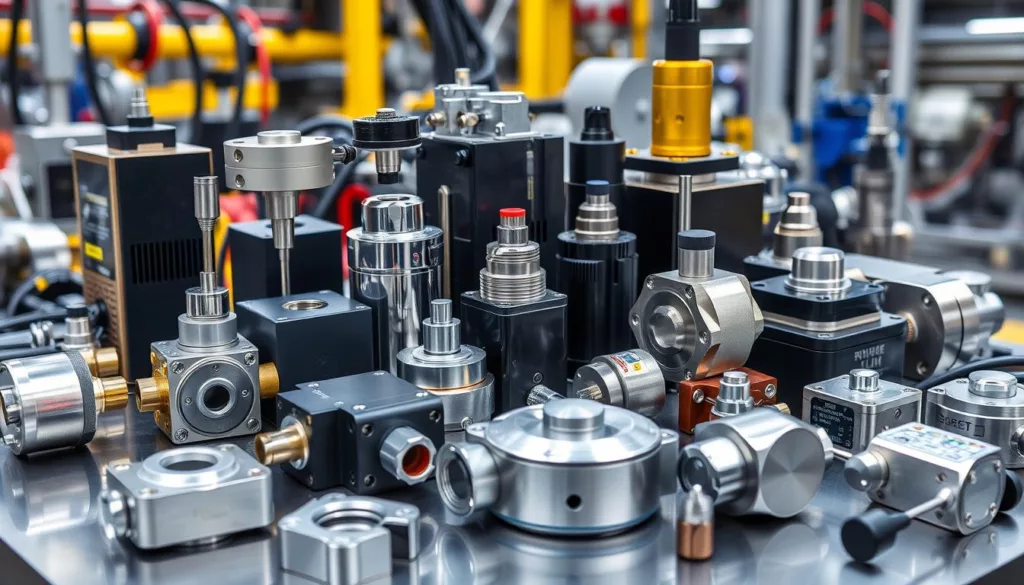

Types of Force Sensors

There are several types of force sensors, each with unique characteristics suited to specific applications. Below are the primary types:

1. Strain Gauge Load Cells

Strain gauge load cells are among the most common force sensors. They work based on the principle that a material’s electrical resistance changes when it experiences strain. When force is applied, the deformation in the load cell alters its resistance, producing a measurable signal.

Applications:

- Weighing scales

- Industrial automation

- Structural health monitoring

Advantages:

- High accuracy

- Durable and reliable

- Suitable for a wide range of force measurements

2. Piezoelectric Force Sensors

These sensors use piezoelectric materials that generate an electrical charge in response to applied force. They are particularly effective in measuring dynamic forces, such as impact or vibration.

Applications:

- Aerospace and defense

- Vibration monitoring

- Biomedical force sensing

Advantages:

- High-frequency response

- Compact design

- Suitable for dynamic force measurements

3. Capacitive Force Sensors

Capacitive force sensors detect force through changes in capacitance between two conductive plates. As force is applied, the distance between these plates changes, altering the capacitance value.

Applications:

- Touch-sensitive screens

- Robotics and automation

- Biomedical devices

Advantages:

- High sensitivity

- Low power consumption

- Suitable for small-scale force detection

4. Magnetic Force Sensors

These sensors use the principle of magnetic field variation to measure force. They detect changes in the magnetic field strength when a force is applied.

Applications:

- Non-contact force measurement

- Magnetic levitation systems

- Position detection in industrial automation

Advantages:

- Non-contact operation

- High precision

- Long lifespan

5. Optical Force Sensors

Optical force sensors use changes in light intensity, phase, or wavelength to detect force. They are highly sensitive and immune to electromagnetic interference.

Applications:

- Harsh environment monitoring

- Medical devices

- Aerospace engineering

Advantages:

- High accuracy

- Immune to electrical noise

- Suitable for high-precision applications

6. Piezoresistive Force Sensors

These sensors rely on materials whose electrical resistance changes under mechanical stress. They are commonly used in pressure sensing and micro-scale force measurements.

Applications:

- Pressure sensors

- Wearable force measurement devices

- Microelectromechanical systems (MEMS)

Advantages:

- Simple design

- Cost-effective

- Compact and lightweight

7. Resonant Force Sensors

These sensors measure force by detecting changes in the resonant frequency of a mechanical structure.

Applications:

- Scientific research

- Precision manufacturing

- Quality control systems

Advantages:

- High sensitivity

- Excellent long-term stability

- Ideal for precise force measurement

Applications of Force Sensors

Force sensors are widely used across industries, including:

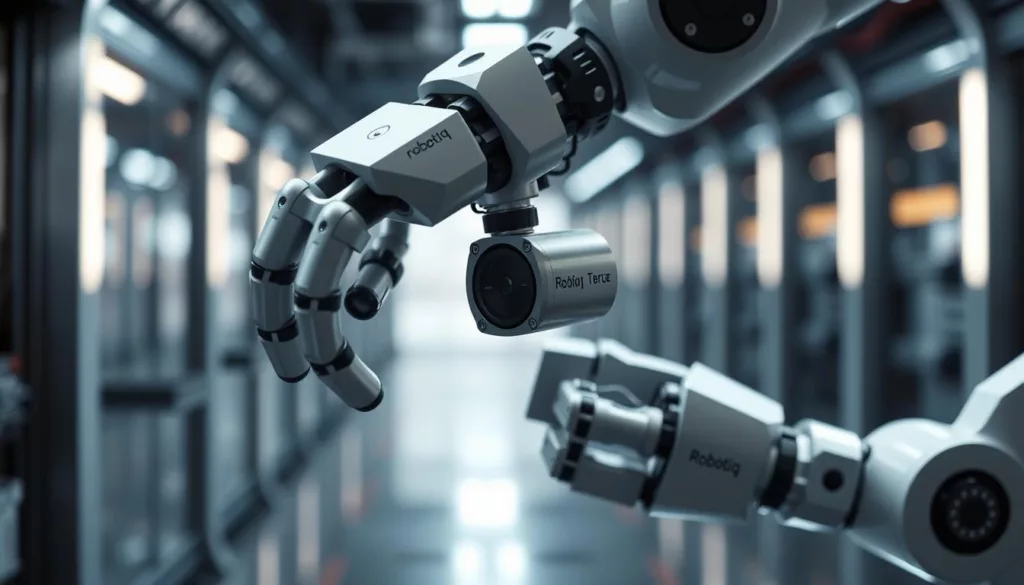

- Industrial Automation: Ensuring accurate force application in assembly lines and robotics.

- Medical Devices: Measuring forces in prosthetics, surgical instruments, and rehabilitation equipment.

- Automotive Industry: Monitoring brake force, airbag deployment, and tire pressure.

- Consumer Electronics: Enabling pressure-sensitive touchscreens and haptic feedback mechanisms.

- Aerospace: Measuring forces acting on aircraft structures and components.

Benefits of Using Force Sensors

- Enhanced Safety: Prevents equipment failures by detecting excessive force loads.

- Improved Accuracy: Provides precise force readings for better process control.

- Increased Efficiency: Automates measurements, reducing human error.

- Cost Savings: Helps optimize resource utilization by minimizing material waste.

Choosing the Right Force Sensor

Selecting the right force sensor depends on several factors:

- Measurement Range: Choose a sensor that matches the expected force range.

- Sensitivity & Accuracy: Consider application-specific accuracy requirements.

- Environmental Conditions: Account for factors such as temperature, humidity, and interference.

- Size & Form Factor: Ensure compatibility with the mechanical setup.

- Cost & Reliability: Balance cost-effectiveness with long-term performance.

Conclusion

Understanding the different types of force sensors and their applications can help industries optimize their processes and improve product quality. Whether it’s strain gauge load cells, piezoelectric sensors, or capacitive force sensors, each type offers unique benefits tailored to specific use cases. By selecting the appropriate force measurement sensor, businesses can enhance precision, efficiency, and overall operational performance.