Introduction

In various industries, accurately measuring force is crucial for optimizing performance, ensuring safety, and maintaining quality control. Force sensors play a pivotal role in this process by detecting and quantifying applied forces in different applications. From industrial automation to robotics and medical devices, these sensors provide essential data for precise force measurement. In this article, we will explore the working principles, types, and applications of force sensors, helping you understand their significance in modern technology.

What Are Force Sensors?

A force sensor is a device designed to measure the force exerted on an object. These sensors convert mechanical force into an electrical signal that can be analyzed for various applications. They are widely used in industries such as manufacturing, automotive, aerospace, healthcare, and consumer electronics.

How Do Force Sensors Work?

Force sensors operate on different principles depending on their type. The most common mechanisms include:

- Strain Gauge Technology: This method relies on the deformation of a strain gauge, which changes resistance in response to applied force. The resistance variation is converted into an electrical signal.

- Piezoelectric Effect: Certain materials generate an electrical charge when subjected to mechanical stress. This charge is measured to determine the applied force.

- Capacitive Sensing: A force changes the distance between capacitor plates, altering capacitance, which is then measured.

- Hydraulic and Pneumatic Systems: These sensors use fluid pressure to measure force indirectly.

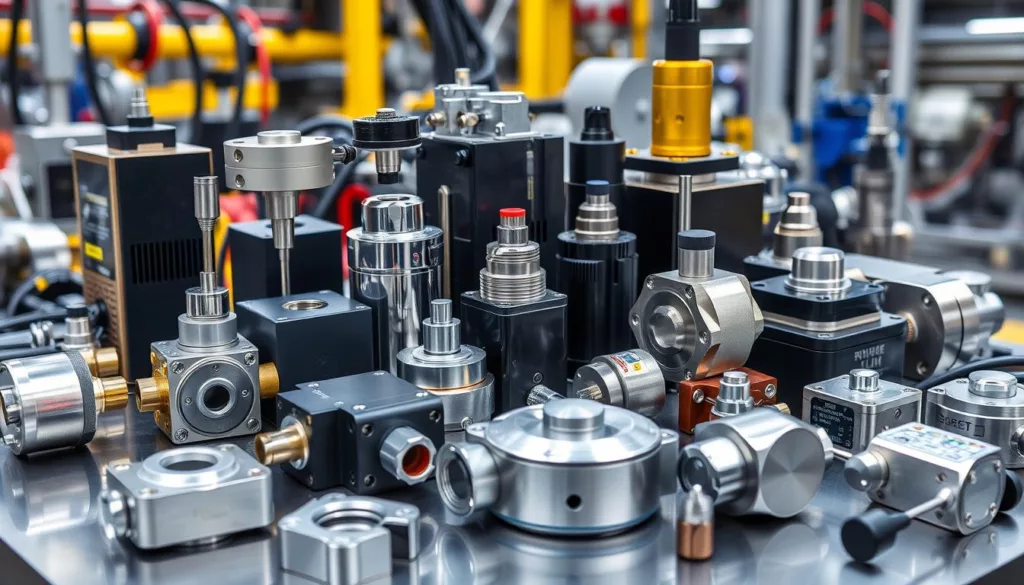

Types of Force Sensors

Several types of force sensors are available, each suited for specific applications:

1. Load Cells

Load cells are widely used for measuring weight and force. They come in various forms such as:

- Compression Load Cells – Measure force applied in a straight line.

- Tension Load Cells – Measure force exerted when pulling.

- Bending Beam Load Cells – Used for measuring forces in weighing scales and structural testing.

2. Torque Sensors

These measure rotational force or torque in machinery and vehicles, ensuring proper functioning of engines and mechanical components.

3. Piezoelectric Force Sensors

Used in high-frequency force measurement applications, such as vibration analysis and dynamic force monitoring.

4. Capacitive Force Sensors

Commonly found in touchscreens and precision measurement instruments.

5. Hydraulic and Pneumatic Force Sensors

Typically used in industrial automation and heavy machinery for force control applications.

Applications of Force Sensors

Force sensors play a vital role in various industries, including:

- Industrial Automation: Ensuring precision in manufacturing and assembly lines.

- Robotics: Enabling robots to interact with objects and apply appropriate force.

- Automotive Industry: Measuring torque and force in vehicle testing.

- Medical Equipment: Used in prosthetics, surgical instruments, and patient monitoring devices.

- Aerospace: Essential in aircraft testing and safety mechanisms.

Choosing the Right Force Sensor

When selecting a force sensor, consider the following factors:

- Measurement Range: Ensure the sensor can handle the expected force levels.

- Accuracy and Sensitivity: Choose a sensor that meets your precision requirements.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals.

- Mounting and Integration: Ensure compatibility with existing systems.

Conclusion

Force sensors are indispensable in modern technology, providing crucial data for industrial automation, robotics, healthcare, and more. Understanding their working principles, types, and applications helps in selecting the right sensor for your needs. Whether you’re involved in manufacturing, automotive, or medical research, leveraging the right force sensor ensures accuracy, efficiency, and safety in your operations.

Call to Action

Looking for high-quality force sensors? XJCSENSOR specializes in customized sensor solutions for industrial automation, robotics, automotive, medical, and other sectors. Contact us today to explore our advanced sensor technologies!