In the fast-paced world of industrial automation, torque sensors are key. They measure the rotational force, or torque, in mechanical systems. This lets industrial teams keep an eye on their work, from assembly to power generation.

Measuring torque is vital for keeping machines running well and safely. It also boosts productivity. With torque sensors, teams can spot problems early and make smart choices to improve their work. This article will explore how torque sensors work, the different ways to measure torque, and their impact on industrial automation.

Key Takeaways

- Torque sensors are essential for monitoring and optimizing the performance of industrial machinery and equipment.

- These devices provide real-time feedback on the rotational force applied to mechanical systems, enabling better control and efficiency.

- Torque measurement is critical for ensuring the safety and reliability of industrial operations, from assembly lines to power generation.

- Advancements in sensor technology have led to the development of highly accurate and adaptable torque measurement solutions for a wide range of industrial applications.

- Integrating torque sensors into industrial automation systems can enhance productivity, quality control, and overall operational efficiency.

Fundamentals of Torque Sensing Technology

It’s key to grasp the basics of torque sensing tech for use in industry. Torque is the force that makes things turn. It’s vital in many factory and automation tasks for precise force measurement, load monitoring, and process control.

Basic Principles of Torque Measurement

Measuring torque is about finding the twisting force on a system. This is done by seeing how much a part bends under force. Sensors with strain gauges or piezoelectric elements turn this force into useful data.

Types of Torque Sensing Methods

- Strain gauge-based torque sensors: Measure the bending of a shaft to find the torque.

- Piezoelectric torque sensors: Use the piezoelectric effect to make an electric signal from the torque.

- Optical torque sensors: Detect twisting with fiber optic or laser tech.

- Magnetoelastic torque sensors: Change in magnetic properties shows the torque applied.

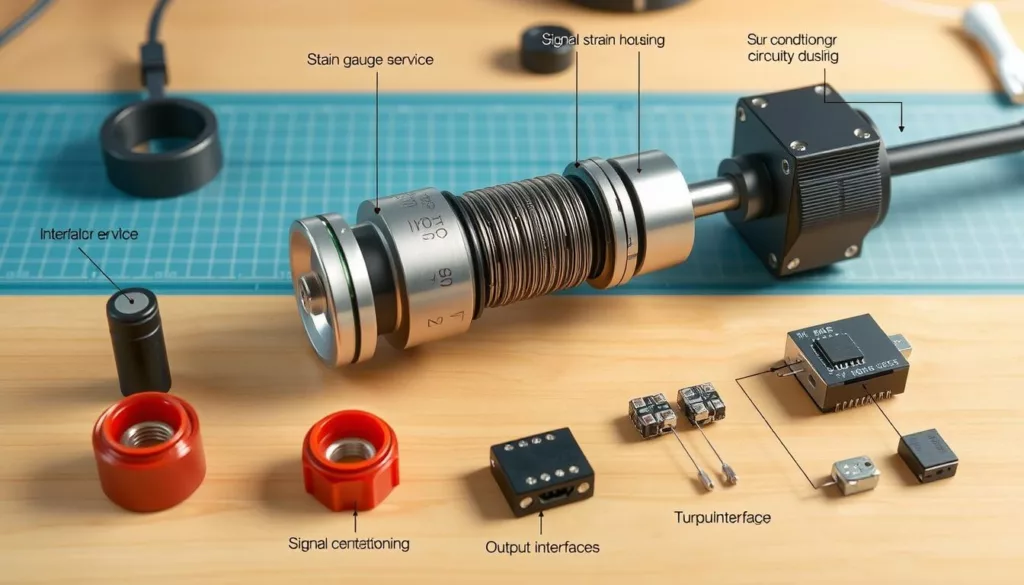

Key Components and Their Functions

Systems for sensing torque have important parts. Each part does a key job:

| Component | Function |

|---|---|

| Sensing Element | Measures the applied torque and turns it into an electric signal. |

| Signal Conditioning Electronics | Boosts, filters, and works on the electric signal from the sensing element. |

| Data Acquisition and Processing | Makes the signal digital for analysis and watching. |

| Calibration and Compensation | Makes sure torque measurements are right by adjusting for outside factors. |

Knowing these basics helps industry experts use torque sensing tech well. This boosts their force measurement, load monitoring, and process control skills.

How do torque sensors work in industrial applications?

Torque sensors are key to keeping industrial operations safe and efficient. They measure the rotational force, or torque, on mechanical systems. This data helps improve performance and avoid failures.

At the core of a torque sensor is the strain measurement principle. When a shaft or rotating part experiences stress, the sensor’s gauges detect tiny changes. These changes are then turned into an electrical signal. This signal is processed to show the torque value, which is monitored by control systems.

- Strain gauge-based torque sensors are reliable and sensitive. They can spot even small changes in torque.

- Optical and magnetoelastic torque sensors use different methods. Each has its own strengths in accuracy, speed, and resistance to environmental factors.

- Torque sensors can process data in real-time. This allows operators to make quick decisions and solve problems before they get worse.

| Torque Sensor Type | Key Features | Typical Applications |

|---|---|---|

| Strain Gauge | Reliable, sensitive, cost-effective | Machinery, power tools, industrial automation |

| Optical | Accurate, fast response, immune to electromagnetic interference | High-speed rotational equipment, test benches |

| Magnetoelastic | Rugged, low maintenance, suitable for harsh environments | Automotive, aerospace, oil and gas industry |

By watching torque levels, operators can make their equipment work better. They can spot problems early and keep their operations safe. Using torque sensors in automation systems helps make decisions based on data. This boosts productivity, efficiency, and reliability.

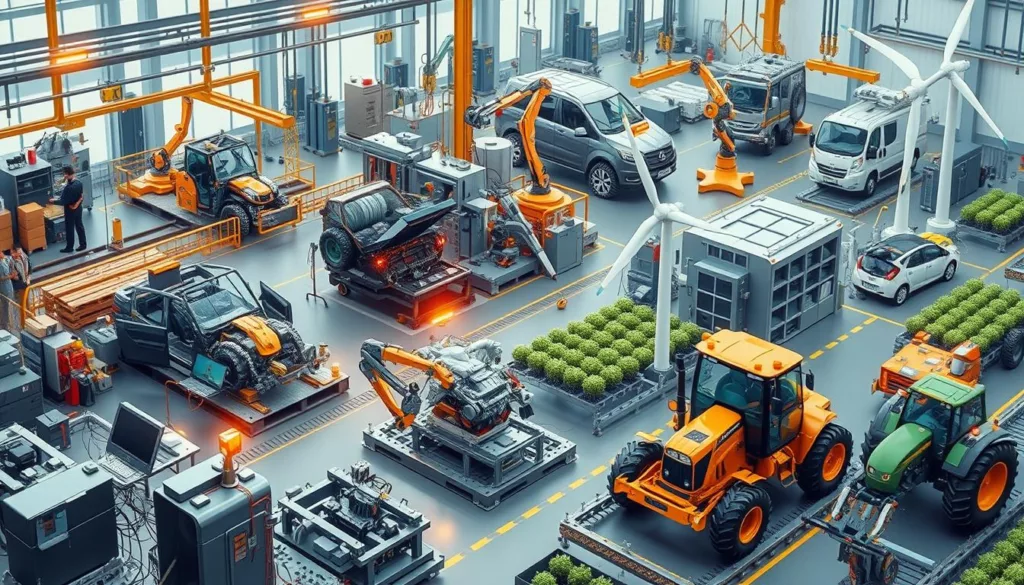

Applications Across Different Industrial Sectors

Torque sensors are key in many industries. They help keep quality, efficiency, and reliability high. They are used in manufacturing, the automotive world, and power generation, changing how businesses work.

Manufacturing and Assembly Lines

In manufacturing and assembly, torque sensors are vital for quality assurance. They watch torque levels closely, spotting problems early. This makes products consistent, cuts down on waste, and boosts efficiency.

Automotive Industry Applications

The car world benefits a lot from torque sensors. They are used in drivetrain, braking, and engine parts for better performance and equipment maintenance. They help find issues, plan maintenance, and make cars safer and more reliable.

Power Generation and Energy Sector

In power and energy, torque sensors are essential. They check the health of turbines, generators, and wind farms. This info lets operators fix problems quickly and run systems more efficiently.

| Industry Sector | Torque Sensor Applications | Key Benefits |

|---|---|---|

| Manufacturing and Assembly | Quality assurance, tightening process optimization | Consistent product quality, reduced waste, enhanced efficiency |

| Automotive | Drivetrain, braking systems, engine assembly | Optimal performance, improved reliability and safety |

| Power Generation and Energy | Turbine, generator, and wind farm monitoring | Proactive equipment maintenance, improved efficiency |

“Torque sensors have become indispensable in various industries, revolutionizing the way we approach quality assurance and equipment maintenance.”

Benefits of Implementing Torque Sensors in Manufacturing

The manufacturing world is changing fast, and torque sensors are key for process control and quality assurance. These advanced tools bring many benefits. They improve how things work, make products better, and boost profits.

Torque sensors are great for keeping an eye on important parts of making things. They measure twisting forces during production. This helps spot problems early, fine-tune machines, and keep product quality up. It means less waste, more products, and better work flow.

- Precise monitoring of critical manufacturing processes

- Identification of problems for quick fixes

- Adjusting machines for better product quality

- Less waste and more products

Also, torque sensors help a lot with quality assurance. They give accurate data on production forces. This lets makers catch and stop defects early. So, only the best products get to customers, making everyone happy.

“Using torque sensors has changed our game. We’ve seen better product quality and less waste. This has saved us money and made customers happier.”

In short, using torque sensors in making things has many good points. They help control processes better and ensure quality. These smart tools are changing how makers work and make products. They help businesses be more productive, profitable, and make customers happier.

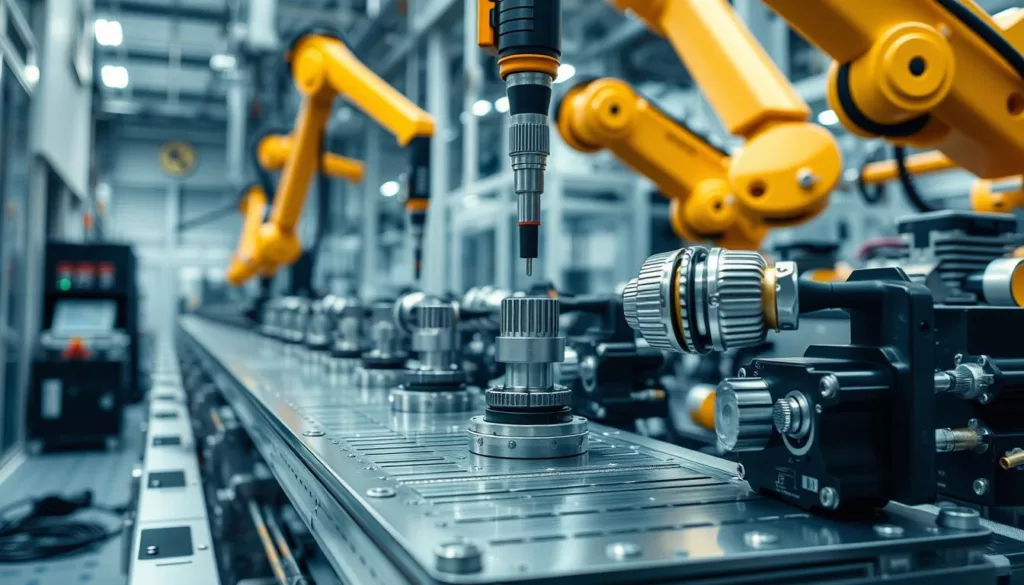

Integration with Industrial Automation Systems

Industrial automation is key in today’s manufacturing. It’s important to add torque sensors to these systems. This helps make production better, improves product quality, and keeps things safe.

Data Acquisition and Processing

Torque sensors are essential for collecting data. They track torque levels, rotational speeds, and more. This info helps automation systems make smart choices, spot problems, and improve production.

Communication Protocols and Interfaces

Torque sensors use different ways to send data to automation systems. This lets manufacturers watch over things from afar, fix problems quickly, and control systems better.

Real-time Monitoring Capabilities

With torque sensors in automation systems, manufacturers can watch processes as they happen. This helps them find and fix issues fast, keep production smooth, and make sure products are top-notch. It all adds up to more work done and less time lost.

“Integrating torque sensors into industrial automation systems is a game-changer, unlocking new levels of visibility, control, and optimization across a wide range of manufacturing operations.”

Maintenance and Calibration Requirements

Keeping equipment maintenance accurate and reliable is key for industries that need precise torque sensors. Regular calibration is vital to keep sensors giving reliable readings. This keeps operational safety high and makes equipment work better and last longer.

A good equipment maintenance plan for torque sensors includes several important steps:

- Regular calibration checks to make sure sensors are accurate

- Preventive maintenance like cleaning and checking for wear

- Fixing any problems quickly to keep operational safety up

- Keeping detailed records of all maintenance and calibration

| Calibration Frequency | Recommended Practices |

|---|---|

| Annually |

|

| Monthly |

|

Following these equipment maintenance and calibration tips helps keep torque sensing systems accurate, reliable, and safe for a long time.

“Proper maintenance and calibration are essential for maximizing the performance and longevity of industrial torque sensors.”

Quality Assurance and Process Optimization

In the world of industrial manufacturing, quality assurance and process optimization are key. Torque sensors are vital for these goals. They help detect errors, monitor performance, and ensure quality control.

Error Detection and Prevention

Torque sensors can spot problems in production. They watch torque levels to find any issues. This helps fix problems fast, cutting waste and improving quality.

Performance Monitoring Systems

Torque sensors help track how well industrial operations are doing. They monitor torque in real-time. This lets manufacturers use equipment better, find ways to improve, and meet production goals.

Quality Control Implementation

Torque sensors are key for quality control. They give precise data to check product specs and process stability. This helps keep quality high.

| Key Benefits of Torque Sensors in Quality Assurance | Metrics Monitored |

|---|---|

| Error detection and prevention | Torque levels, deviations, and anomalies |

| Performance monitoring and optimization | Efficiency, productivity, and process stability |

| Comprehensive quality control implementation | Product specifications, process compliance, and quality assurance |

“Torque sensors are essential tools for maintaining the highest quality standards and optimizing industrial processes. Their ability to detect errors, monitor performance, and inform quality control measures is invaluable in today’s competitive manufacturing landscape.”

Safety Considerations and Compliance Standards

Operational safety is key when using torque sensors in industrial automation. These tools are vital for keeping the workplace safe. They make sure machines and processes follow strict rules and safety steps.

Torque sensors are important for watching torque levels. They prevent machines from getting too much load, which could cause big problems. By watching torque, workers can spot and fix issues fast, keeping everyone safe.

Torque sensors also help follow safety rules and standards. Groups like OSHA and ISO set rules for using industrial equipment. These sensors help make sure everyone follows these rules, keeping workers and the public safe.

| Compliance Standard | Key Requirements |

|---|---|

| OSHA 1910.147 | Lockout/Tagout procedures for the control of hazardous energy |

| ISO 13849-1 | Safety of machinery – Safety-related parts of control systems |

| IEC 61508 | Functional safety of electrical/electronic/programmable electronic safety-related systems |

Using torque sensors in industrial systems makes things safer and shows a commitment to following rules. This helps build a safe and trustworthy work environment. It’s good for workers and the community.

“Ensuring operational safety and compliance is a fundamental responsibility for any organization involved in industrial automation. Torque sensors are a critical component in this endeavor, providing the data and insights needed to maintain a safe and efficient production environment.”

Conclusion

Torque sensors have a big impact in today’s industries. We’ve looked at how they work, the different types, and their importance. They help make things better, safer, and more precise in many fields.

In places like factories, car makers, and power plants, torque sensors are key. They help track and analyze data in real time. This lets workers improve how things are done and follow safety rules closely.

The need for better industrial tools is rising. XJCSENSOR is leading the way with new, tailored sensor solutions. By working together, we can make industries more efficient and innovative, shaping their future.