At XJCSENSOR, we lead in advanced tension sensor solutions for web and textile industries. Our expertise in customized, high-quality sensor technologies boosts production efficiency and quality. We help manufacturers optimize materials across various applications.

We offer innovative load cell integrations and non-contact tension measurement systems. Our goal is to drive the future of industrial automation with sensor innovation.

Our sensor solutions provide top precision, reliability, and versatility. They meet the changing needs of modern web and textile manufacturing. With cutting-edge sensing technologies and advanced data processing, we help clients achieve better process control and material monitoring.

This leads to increased productivity and profitability. Predictive maintenance is also a key benefit.

Key Takeaways

- Innovative sensor solutions tailored for web and textile applications

- Customized technologies to enhance production efficiency and quality control

- Leveraging advanced data processing and monitoring capabilities

- Delivering industry-leading precision, reliability, and versatility

- Empowering clients to achieve optimal material optimization and process control

Understanding Load Cell Technology in Modern Textile Manufacturing

In the fast-paced world of textile production, load cell technology is a big leap forward. These advanced sensors are changing how textile machines work. They make operations more accurate, efficient, and productive for everyone in the industry.

Types of Load Cells for Textile Applications

Textile makers have many specialized load cell options to fit their needs. From small S-type load cells to strong shear beam load cells, each type is made to give exact, live feedback on important things like tension, force, and weight.

- S-Type Load Cells: These are small and flexible, perfect for tight spaces in textile machines and web handling gear.

- Shear Beam Load Cells: Tough and dependable, these are used in heavy textile processing machines. They give exact force and tension readings.

- Bending Beam Load Cells: Great for precise weight and force checks, these are best for textile lines and packaging setups.

Core Benefits of Load Cell Integration

Adding load cell tech to textile making brings many benefits, like:

- Improved Process Control: Load cells give real-time data. This lets textile makers watch and tweak key factors, like fabric tension and winding forces, to better quality and consistency.

- Enhanced Productivity: Load cells give exact feedback. This helps make textile machines work better, needing less manual tweaking and boosting overall machine use.

- Increased Operational Safety: Load cells spot and stop problems, like too much force or material breakage. This keeps both machines and people safe.

Installation Requirements and Considerations

Putting load cell tech into textile machines needs careful thought and planning. Things like where to mount sensors, how to run cables, and how to handle signals must be sorted out for smooth setup and reliable use. Talking to experts in textile machinery sensors can help manufacturers get the most out of load cell solutions.

“Load cell technology has changed textile making, letting us reach new heights of precision, efficiency, and safety.”

| Load Cell Type | Key Applications | Advantages |

|---|---|---|

| S-Type Load Cells | Textile machinery, web handling equipment | Compact design, high accuracy, versatile mounting |

| Shear Beam Load Cells | Heavy-duty textile processing equipment | Robust construction, reliable performance, precise force measurement |

| Bending Beam Load Cells | Textile production lines, packaging systems | High-accuracy weight and force measurement, easy integration |

Tension Sensor Solutions for Web and Textile Applications

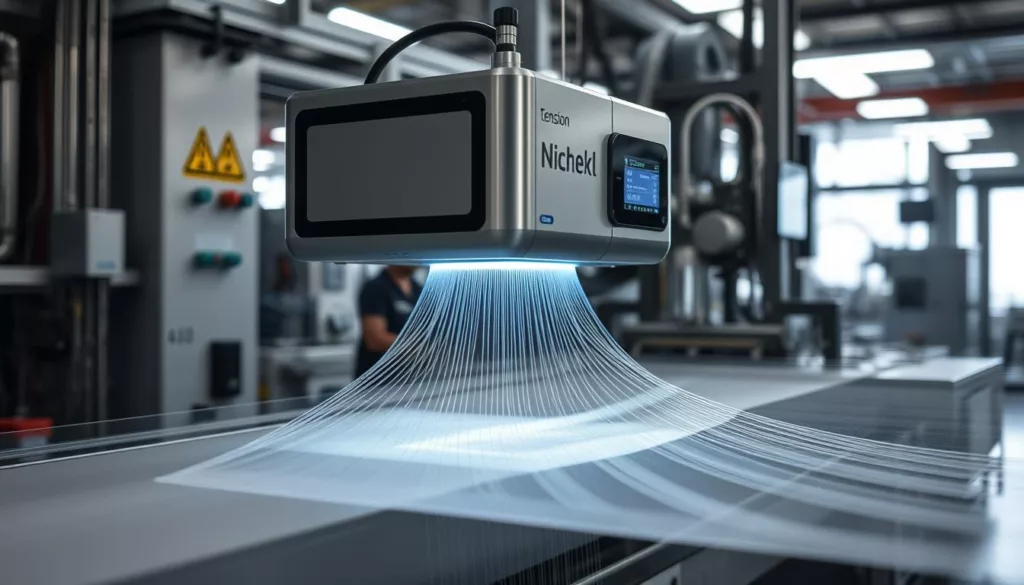

In the world of web handling and textile making, keeping tension right is key. XJCSENSOR has created special tension sensor solutions for these fields. They help keep product quality high and production running smoothly.

Our web handling solutions use top-notch industrial automation sensors. These sensors watch material tension control all the time. They give real-time data on web tension, helping make precise adjustments. This ensures products are always up to standard and cuts down on waste.

- Robust load cell technology for accurate tension measurement

- Customizable sensor configurations to fit diverse web and textile applications

- Seamless integration with existing automation systems for centralized control

In the textile world, our tension sensors are very important. They help keep delicate fabrics and yarns in top shape. Our customers see better product quality, less downtime, and more efficiency in their work.

“XJCSENSOR’s tension sensor solutions have been a game-changer for our textile production line. The real-time data and precise control have significantly improved our product quality and reduced material waste.”

XJCSENSOR knows the web handling and textile industries well. We keep making our tension sensor tech better. This helps our customers stay ahead in modern manufacturing.

Advanced Material Tension Monitoring Systems

In the world of industrial automation, knowing the exact tension of materials is key. XJCSENSOR‘s advanced systems are at the forefront of this field. They help improve production in many industries, like web handling and textile making.

Real-time Data Processing Capabilities

Our systems use top-notch sensors and algorithms to give real-time tension insights. They constantly analyze data to help manufacturers understand their production better. This knowledge lets them make smart choices and fix problems quickly.

Precision Control Mechanisms

- Our systems use servo-driven actuators for precise tension control. This keeps the tension just right throughout production.

- Advanced feedback and algorithms quickly adjust to any changes. This ensures the material is always handled smoothly and consistently.

- Our systems also have easy-to-use interfaces. Operators can adjust tension settings easily to meet changing needs.

System Integration Protocols

Our solutions fit right into your existing automation systems. This makes setup easy and boosts your investment’s value. They use strong communication protocols and open architecture. This makes them a smart choice for material tension monitoring, web handling solutions, and industrial automation sensors.

| Key Features | Benefits |

|---|---|

| Real-time Tension Monitoring | Optimize production processes with continuous data-driven insights |

| Precision Tension Control | Maintain consistent material handling and web stability |

| Seamless System Integration | Streamline implementation and maximize the value of your investment |

Using XJCSENSOR‘s systems can greatly improve your production’s efficiency, quality, and profits. Check out our full range of solutions to take your operations to the next level. Stay competitive in today’s fast-paced industrial world.

Non-Contact Tension Measurement Technologies

In the world of web and textile making, old ways of measuring tension don’t always work well. But, new non-contact methods are changing the game. They make measuring tension more accurate, reduce wear, and make production smoother.

Leading this change are non-contact tension measurement tools. They use advanced tech like optics, lasers, or electromagnetics to check tension without touching the material. These tools give real-time info on web guiding systems and material tension control. This helps makers run their operations better and keep tight control over important production details.

Unlike old methods that use rollers or touch the material, these new systems don’t touch. This means less chance of damaging the materials. It also means consistent, reliable readings, even in fast and tense situations where old sensors might fail.

| Feature | Benefit |

|---|---|

| Accurate, real-time tension monitoring | Enables precise control and optimization of production processes |

| Reduced equipment wear and maintenance | Lowers operational costs and downtime |

| Versatile integration with web guiding systems | Enhances overall system performance and efficiency |

By using these new non-contact tension measurement tools, web and textile makers can control material tension better. This leads to better product quality, more productivity, and a strong edge in the market.

Web Guiding Systems and Tension Control Integration

At the heart of modern textile and web-based manufacturing lies the seamless integration of web guiding systems and tension control mechanisms. These sophisticated systems work in tandem to optimize material handling, ensure consistent product quality, and enhance overall production efficiency.

Automated Alignment Solutions

Precise web alignment is key for maintaining consistent tension and avoiding costly material waste or defects. Automated web guiding systems use advanced sensor technology and control algorithms. They continuously monitor and adjust the web position, keeping it perfectly centered and aligned throughout the manufacturing process.

Error Detection and Correction Methods

Integrated tension control and material tension monitoring systems play a vital role in identifying and addressing issues. By continuously tracking tension levels, these advanced systems can quickly detect and correct tension-related errors. This minimizes downtime and maximizes production yields.

Performance Optimization Techniques

The seamless integration of web guiding and tension control technologies allows manufacturers to fine-tune their processes. This unlocks new levels of performance optimization. Through data-driven insights and intelligent feedback loops, these systems can continuously adapt to changing conditions. This ensures the production of high-quality, consistent materials.

| Feature | Benefit |

|---|---|

| Automated Alignment | Maintains consistent web positioning and tension, reducing material waste and defects. |

| Error Detection and Correction | Identifies and addresses tension-related issues, minimizing downtime and maximizing production yields. |

| Performance Optimization | Leverages data-driven insights to continuously adapt and improve production processes. |

“By integrating our advanced web guiding systems and tension control technologies, we empower our customers to achieve unprecedented levels of production efficiency and material quality.”

Industrial Force Sensor Applications in Textile Processing

In the fast-paced world of textile making, force sensor technology is key. These sensors help improve quality, cut down on waste, and make processes more efficient. They are used in many textile making steps.

Force sensor integration is vital in the textile field. These sensors check and control important things like tension and force. They give real-time info, helping makers make better products and work smarter.

Also, industrial automation sensors with force tech are changing how textiles are made. They help with things like guiding webs and controlling tension. This leads to better control, finding mistakes, and making the whole process better.

| Application | Benefit | Key Sensor Technology |

|---|---|---|

| Textile Machinery Monitoring | Improved Quality Control, Reduced Waste | Force Sensors, Tension Sensors |

| Automated Web Guiding | Precise Alignment, Optimal Tension | Force Sensors, Position Sensors |

| Intelligent Tension Control | Consistent Material Properties, Process Efficiency | Load Cells, Pressure Sensors |

Using industrial force sensors, textile makers can work better, make better products, and keep up in a tough market. As the field grows, using new sensor tech will be key to its future.

“Sensor technology is revolutionizing the textile industry, enabling manufacturers to achieve new levels of precision, quality, and efficiency.”

Digital Tension Control Solutions for Modern Manufacturing

In today’s fast-changing world of web and textile making, digital tension control is a big leap forward. It uses industrial automation sensors and smart networks to bring unmatched precision and efficiency. It also makes predictive maintenance easier.

Smart Sensor Networks

The growth of digital tension control is thanks to new sensor tech. These smart networks watch over the making process, checking material tension in real-time. This lets makers adjust and improve right away, cutting down waste and downtime.

Cloud-Based Monitoring Systems

Cloud systems work with these smart networks to collect and analyze lots of data. They give a full view of the making process. This helps makers spot problems early and fix them before they get worse. It’s a big step for staying competitive.

Predictive Maintenance Capabilities

Digital tension control is great at spotting and stopping equipment problems before they start. It uses smart analytics to find trends and oddities in data. This way, it warns makers of issues before they cause big problems. It keeps machines running longer and makes making more efficient.

As web and textile making keeps getting better, using digital tension control will be key. It lets companies reach new heights in quality, productivity, and profit. With smart sensors, cloud monitoring, and predictive maintenance, the future looks bright.

Optimizing Production Efficiency Through Sensor Technology

In the fast-paced world of web and textile making, advanced sensor tech is changing the game. It boosts production efficiency, tension sensor solutions, and web handling solutions. This leads to better performance and profits for top manufacturers.

Tension sensors are key in this change. They keep an eye on material tension, making sure it’s just right. This cuts down on web breaks and improves product quality. It also makes the whole process smoother, leading to more output and less waste.

| Key Benefits of Sensor-Driven Optimization | Measurable Impact |

|---|---|

| Improved material handling and web control | 15-20% increase in production throughput |

| Reduced web breaks and material waste | 8-12% reduction in scrap and rework |

| Real-time monitoring and predictive maintenance | 25-30% decrease in unplanned downtime |

Using tension sensor solutions and web handling solutions helps manufacturers a lot. It lets them see and control their processes better. This means teams can make smarter choices, improve workflows, and boost production efficiency.

“Advanced sensor tech has set a new high in our textile making. The real-time data and precise control have changed how we work, making us more productive and profitable.”

As things keep changing, sensor technology will stay key for better production. By using these new tools, forward-thinking makers can reach new heights. They’re setting the stage for a future of top-notch manufacturing.

Implementation Strategies for Tension Control Systems

Setting up a strong tension control system is key for industrial makers wanting better production and quality. At XJCSENSOR, we offer detailed plans to help you through it. We make sure everything works well together and performs at its best.

System Design Considerations

When making a tension control system, you must think about your specific needs. Our experts team up with you to look at your production, materials, and limits. This way, we can suggest the best sensor solutions and controls for you.

Integration Best Practices

Putting a tension control system in place needs careful planning and doing. Our pros help you through it all, step by step. We make sure everything goes smoothly, from setting up sensors to programming the system.

ROI Analysis and Benefits

Getting a tension control system brings real benefits like more work done, better products, and lower costs. Our detailed ROI analysis shows how it saves money and boosts quality over time. With XJCSENSOR, you can make your manufacturing better and stay competitive.