Introduction

Force sensors are essential in many industries, from manufacturing to transportation. They measure force, weight, or pressure accurately, ensuring precise calculations in different applications. Among these, weight load cells are the most common and reliable devices used in weighing systems. But how do they work, and what are the different types available?

Understanding force sensor types helps industries choose the right solution for their needs. This article explores the working principles of load cells, their types, applications, and purchasing considerations.

What is a Force Sensor?

A force sensor is a device that measures force or weight by converting mechanical force into an electrical signal. These sensors are widely used in weighing systems, industrial machinery, and transportation.

Force sensors come in different types, with load cells being the most widely used in modern applications.

How Do Load Cells Work?

A load cell is a type of force sensor that measures weight through strain gauges, hydraulic pressure, or other mechanisms. When force is applied, the load transducer inside the sensor converts the pressure into an electrical signal, which is then processed to determine the weight.

This makes load cells for weighing ideal for industrial applications, from truck scales to precision weighing systems.

Types of Force Sensors

There are several types of force sensors, each suited for different applications. The most common ones include:

- Strain Gauge Load Cells– Used in most industrial weighing applications.

- Hydraulic Load Cells– Ideal for harsh environments without electricity.

- Pneumatic Load Cells– Used where precise pressure control is needed.

- Capacitive Load Cells– Common in precision measurement systems.

Weight Load Cell: The Most Common Force Sensor

A weight load cell is a device used to measure weight in various applications, including industrial load cells, truck scale load cells, and weighing scale load cells. These sensors provide highly accurate readings, making them essential for industries requiring precision.

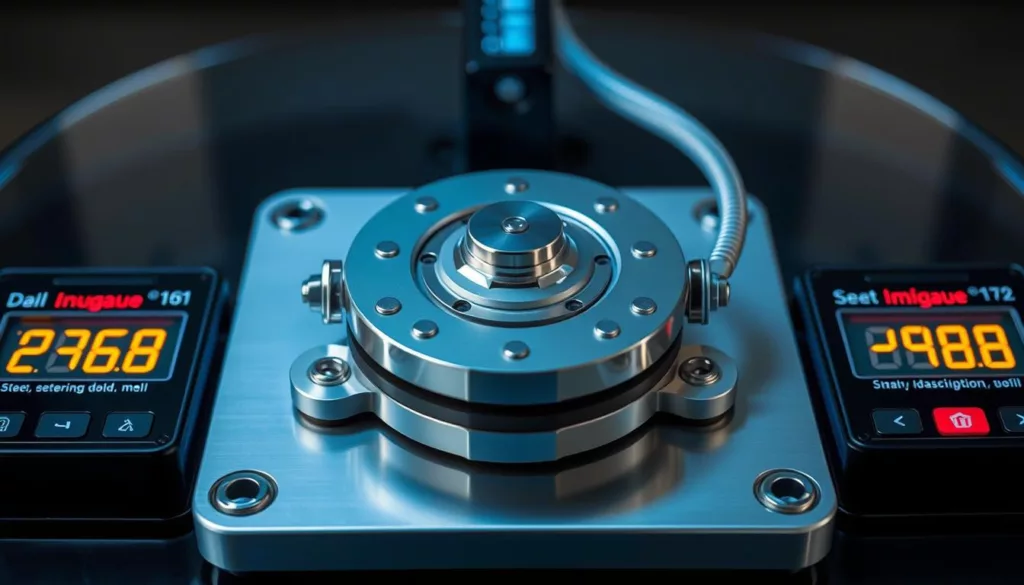

Strain Gauge Load Cells

Strain gauge load cells are the most popular type of load cell sensor. They work by measuring the deformation of a metal component under force. The electrical resistance changes based on the applied load, which is then converted into a weight reading.

Advantages of Strain Gauge Load Cells

✔ High accuracy

✔ Compact and versatile

✔ Suitable for different industrial applications

Hydraulic Load Cells

Hydraulic load cells use fluid pressure to measure weight. When force is applied, the hydraulic fluid compresses, generating a pressure change proportional to the weight.

Key Uses

✔ Heavy-duty industrial applications

✔ Environments with extreme temperatures

✔ No electrical power required

Pneumatic Load Cells

Pneumatic load cells operate using air pressure. These load cells are ideal for highly sensitive applications and environments requiring explosion-proof solutions.

Capacitive Load Cells

Capacitive load cells measure force through changes in electrical capacitance. These are commonly used in precision measurement applications, such as electronic scales.

Load Cell Working Principle

The fundamental working principle of a load cell sensor is based on force-to-electrical signal conversion. A typical load cell circuit consists of:

✔ A sensor that detects force

✔ A transducer that converts force into an electrical signal

✔ An amplifier that processes the signal for accurate readings

Load Cell Sensor in Industrial Applications

Industries rely on load cells for weighing systems in areas like:

✔ Manufacturing – Material weighing and automation

✔ Transportation – Truck scale load cells for cargo weight monitoring

✔ Agriculture – Precision farming and feed measurement

Load Cells for Sale: Where to Buy?

When considering a load cell purchase, buyers should focus on quality, accuracy, and supplier reliability. Some key providers offer loadcell supplies globally for industrial and commercial use.

Factors to Consider

✔ Accuracy and sensitivity

✔ Durability and environmental resistance

✔ Price and supplier reputation

Future Trends in Force Sensor Technology

The future of force sensors is evolving with advancements like wireless load cells, AI-based data analysis, and IoT integration for smarter monitoring systems.

Conclusion

Choosing the right force sensor type depends on the application and industry needs. From weight load cells to hydraulic and capacitive sensors, these devices play a crucial role in precision measurement. Whether you’re looking for load cells for weighing or industrial applications, understanding their working principles ensures accurate and reliable performance.

FAQs

How does a load cell work?

What is the best load cell for industrial applications?

Can load cells be used in harsh environments?

Where can I buy load cells for sale?

What are truck scale load cells?

What factors should I consider when buying a load cell?